1

2

3

4

5

6

7

8

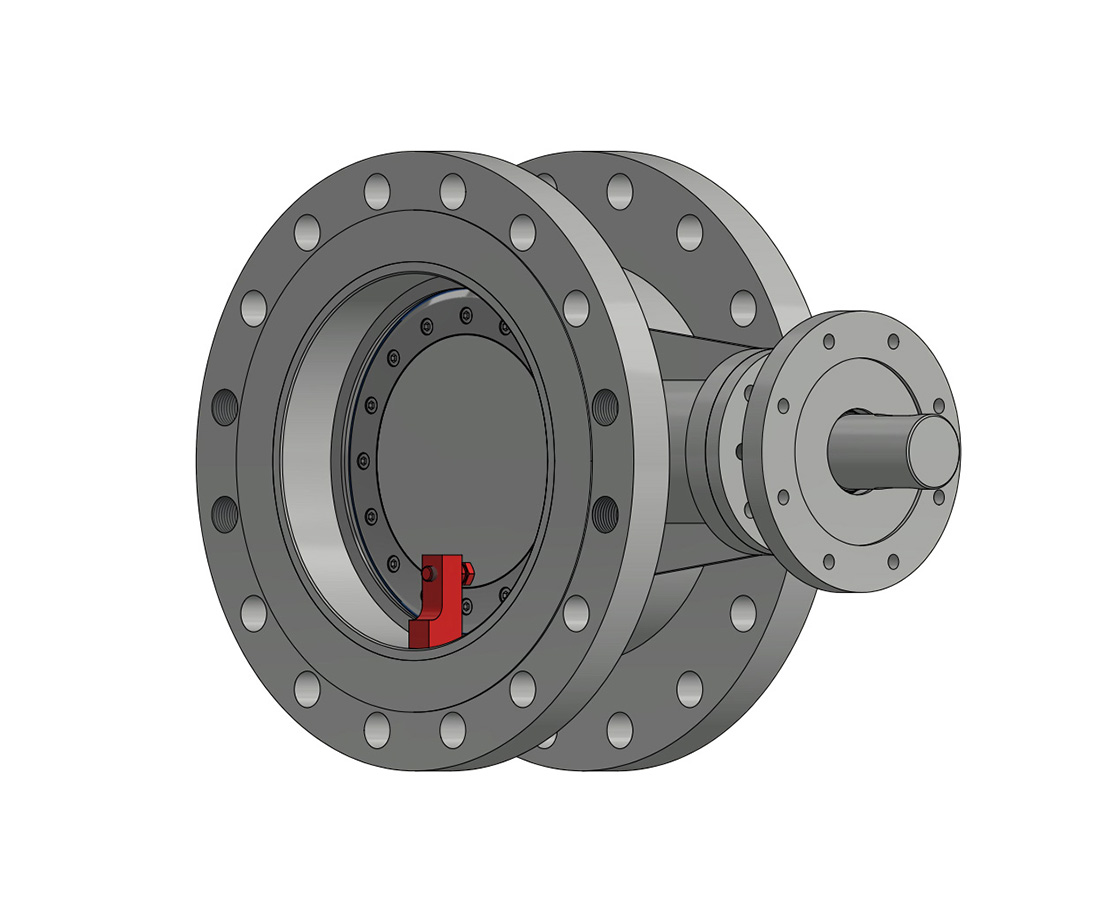

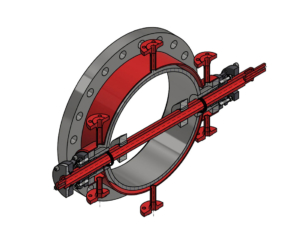

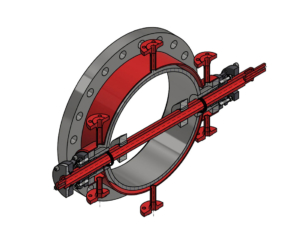

1

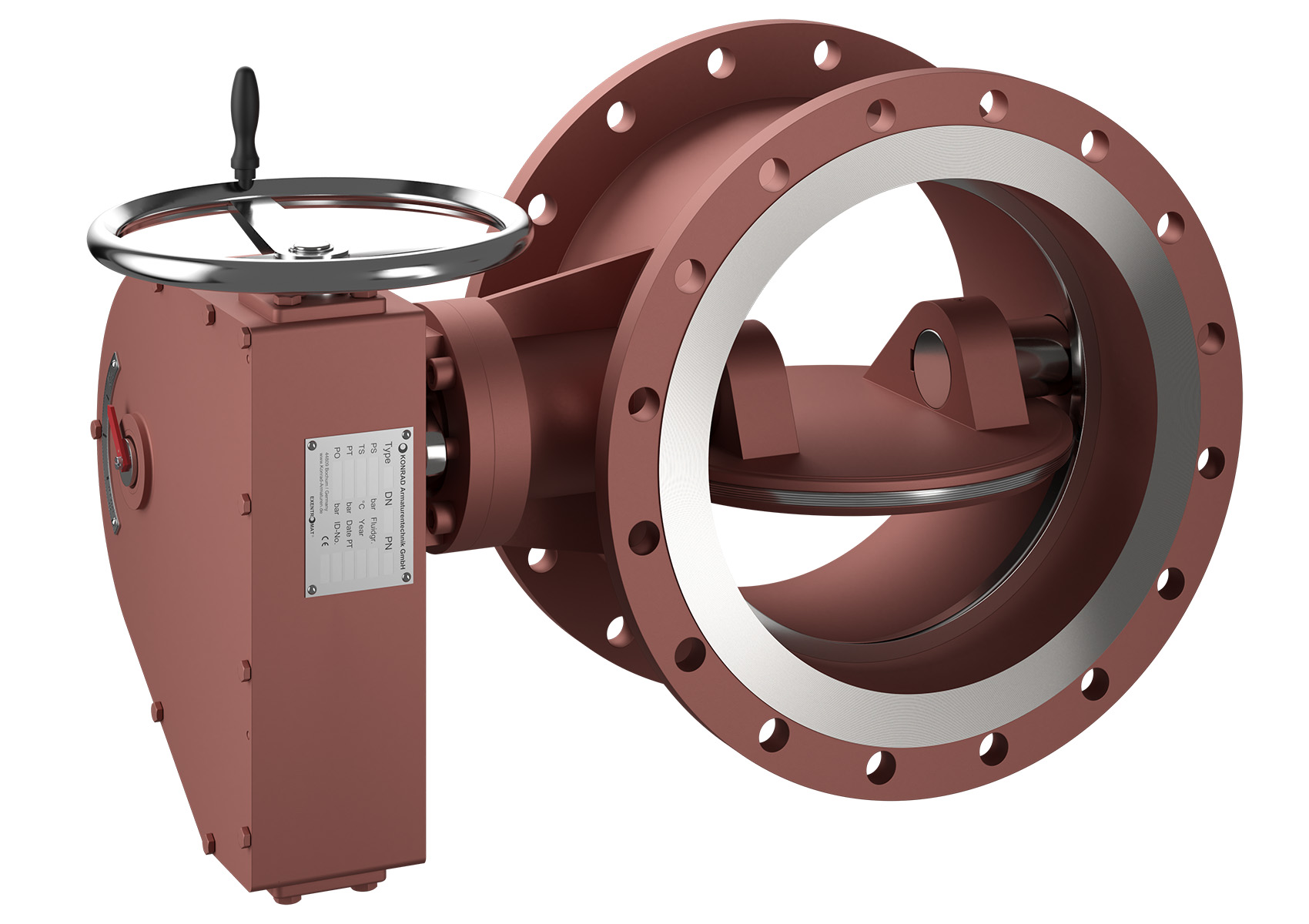

Actuator types

– manual

– electric

– pneumatic

– hydraulic

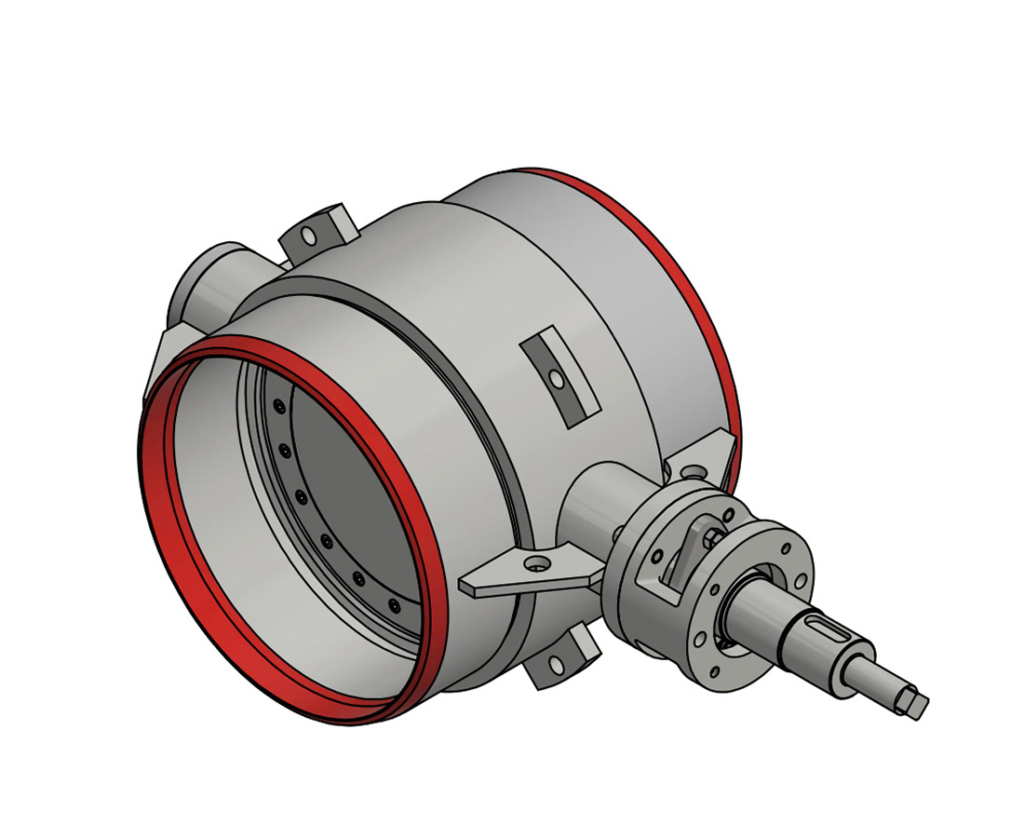

2

Butt ends

3

Heating jacket

4

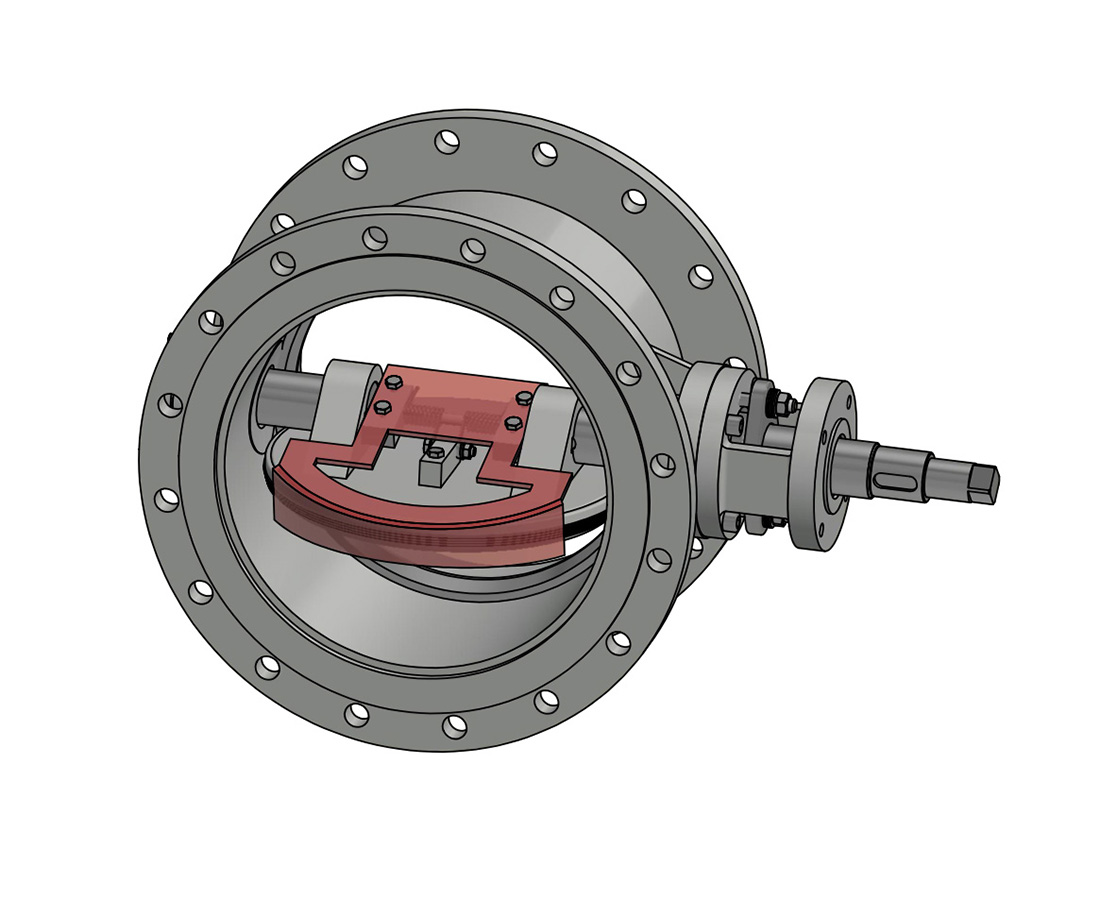

Heated shaft

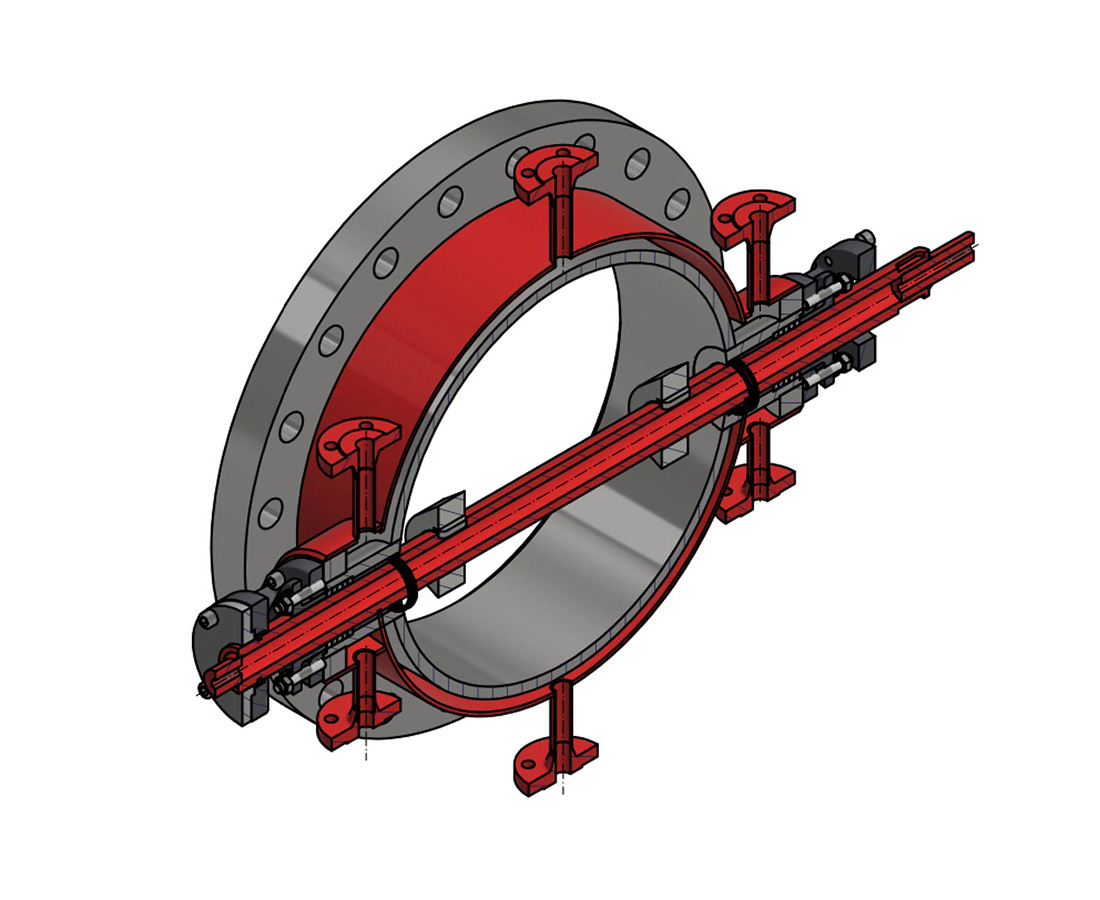

5

Mechanical stroke limitation / limit stop

6

Outer bearings

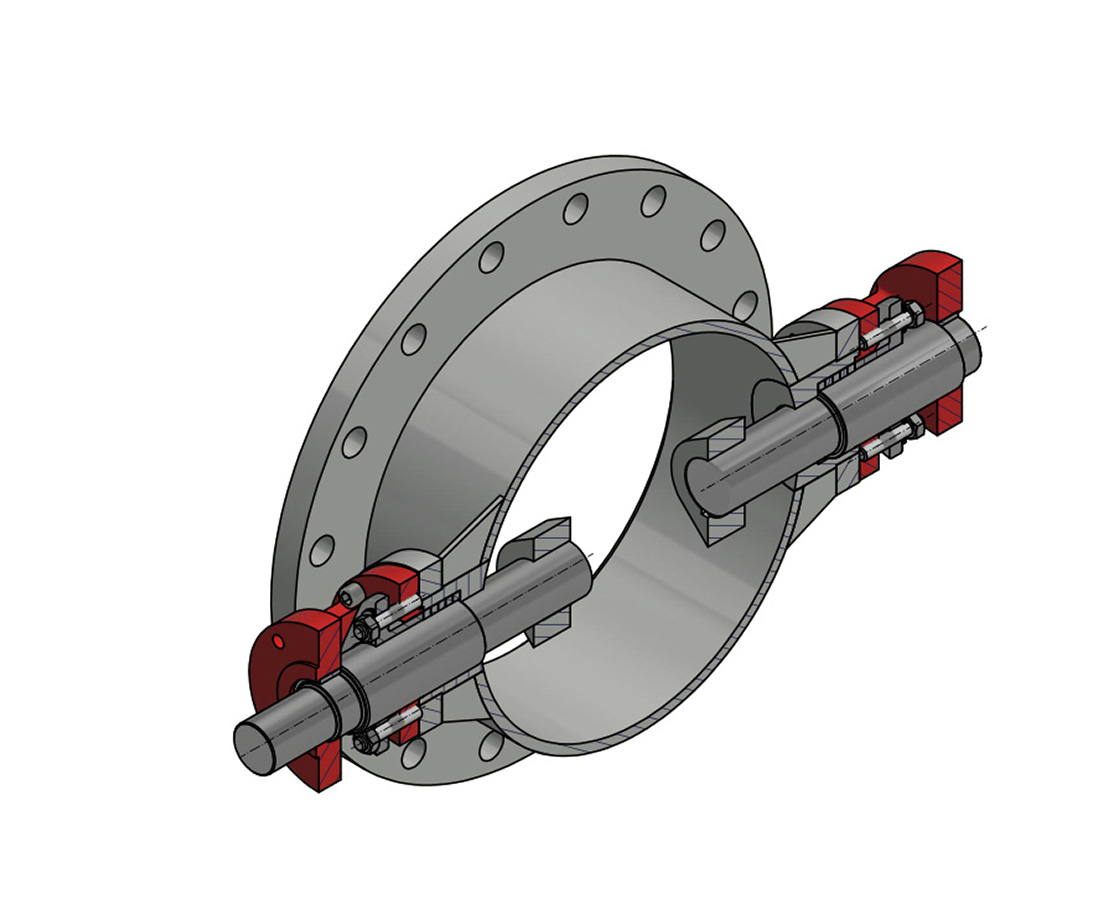

7

Flow protection

8

Coatings

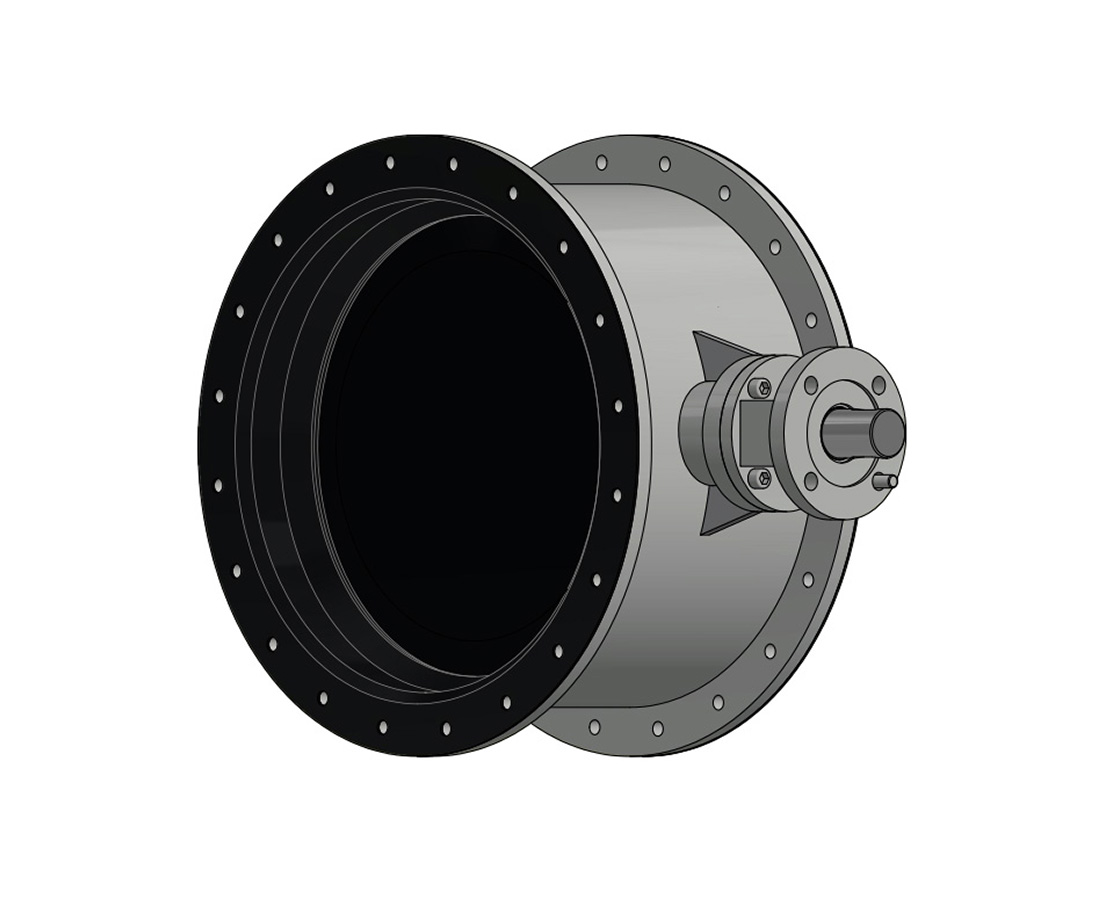

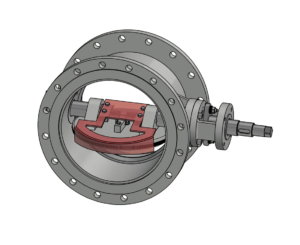

Butt ends

- welded integration into the pipeline

- no risk of leakage

- high safety factor

Heating jacket and heated shaft

- continuous heating of the housing jacket and the shaft by heating medium (e.g. steam or process gas)

- avoids cooling of the medium and thus hardening in the flow-through

Mechanical stroke limitation / limit stop

- ensures optimum positioning of the disc in the housing seat

- reduces friction between the disc seal and the seat ring

- thus reduces wear on the damper seal

Outer bearings

- Use especially with higher media temperatures and media containing solids

- minimises heat transfer from the medium to the bearings

- prevents the medium from penetrating into the shaft bearings

Flow protection

- movable, spring-loaded plate protects the disc seal in the inflow area from abrasion

- ideal for gaseous media with high flow velocities and high solids content

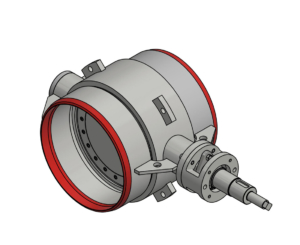

Coatings

Hard rubber coating:

- low-cost alternative to the stainless steel version

- Inner lining of the valve and valve disc with hard rubber coating based on polyisoprene rubber (IR) and styrene butadiene rubber (SBR)

Hard coating:

- increases resistance to abrasion and corrosion.

- application especially at high temperatures and for heavily stressed surfaces

Do you have any special requests? We will be pleased to check the feasibility.

.